Project Elixir supply chain

Welcome!

You found this page, which means you're curious about how and where your design was made. We like that. Here is some info.

If you bought a design made in leather...

The main material

The leather we used for this project is from Spain.

We use cow hides of adult cows & our tannery embosses the leather to give it this grain you can see and feel. This texture is "created" for our bags. The only other way to achieve it would be to use exotic leathers like e.g. crocodile. But we do not want to use leather from animals who are raised only for their leather as it is not sustainable.

The lining

The lining for all the bags is GOTS-certified cotton canvas from Spain. "GOTS" means Global Organic Textile Standard: it's a reliable and globally recognized certification in terms of sustainability.

The cotton itself, from which the fabric is woven, comes from India. The fact that the final textile is GOTS-certified insures that there are no harmful chemicals used during the production of the fabric: among other things, it guarantees that no harmful chemicals are used in the fields, and therefore the GOTS certification protects the people working in those fields.

Exception: for the wallets, the lining is a light-weight woven fabric from Italy. It is a quality used in menswear tailoring (aka. when you buy a nice suit with cotton lining inside).

The hardware elements

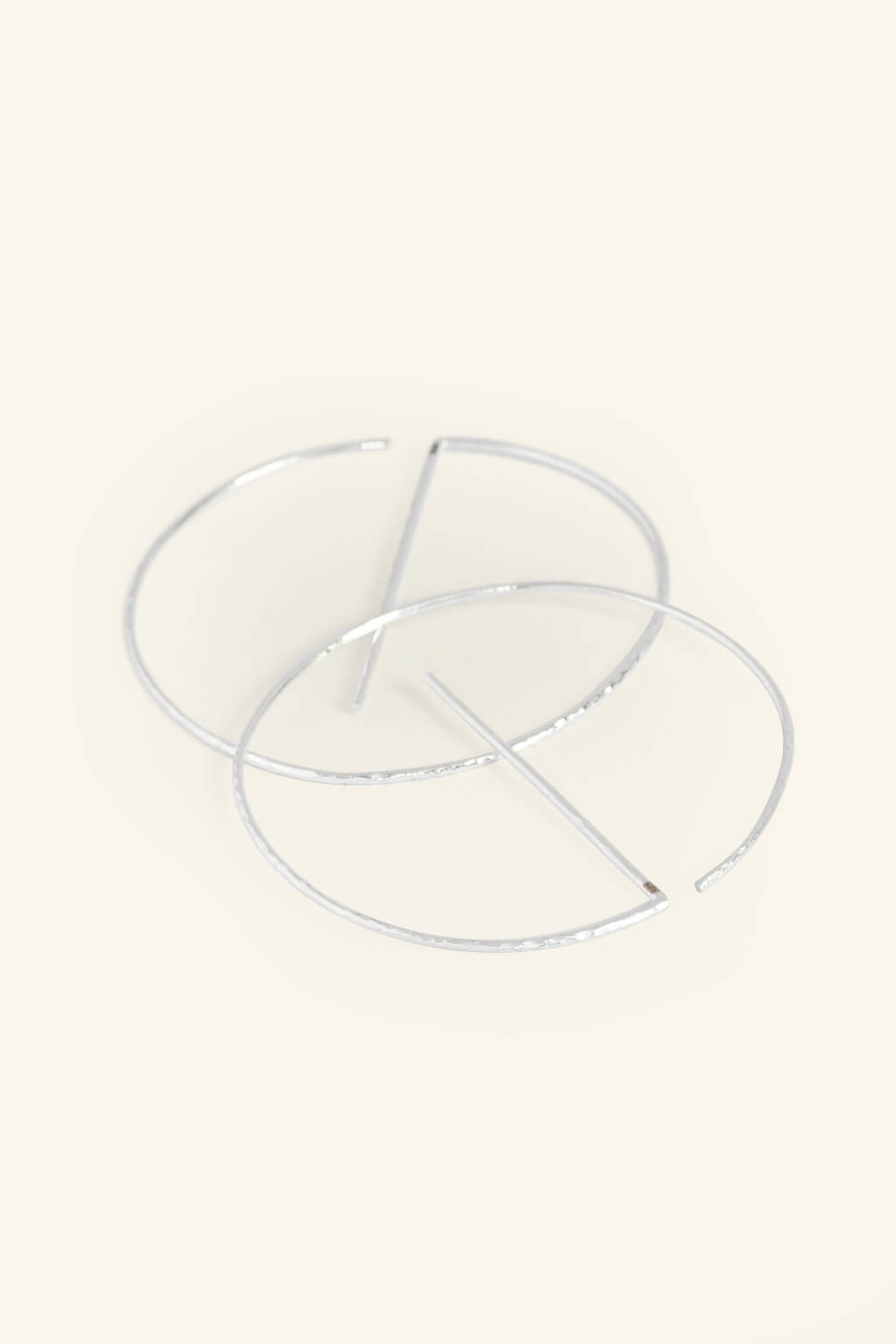

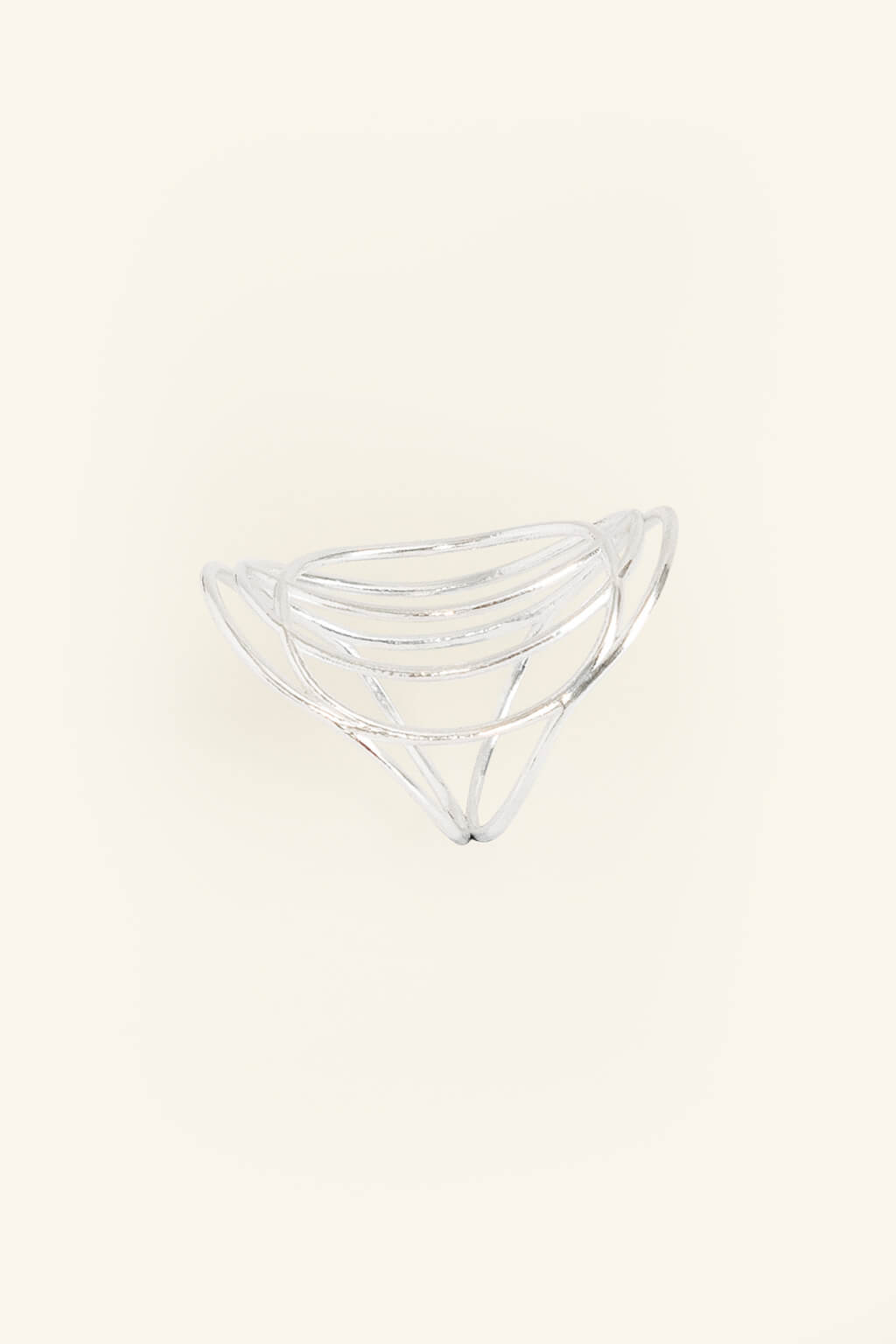

What we call hardware are the metal elements of your bag. These are almost like a jewelry development: each part requires the creation of a unique mold, into which the material is poured. Then comes the polishing & plating steps, just like for jewelry. The only difference is we have 100% Sterling silver inside our jewelry, whereas for this handbag collection we use zamak. Zamak is a mix of several metals which is highly resistant, super durable, and more suited for handbags than solid silver. Silver is much more expensive but also too soft and too bendy for this purpose.

The hardware comes from a French company with a special setup: the technical development and the prototyping take place in France, the final production is in Hong-Kong and the quality control is in France. Initially, we wanted a European production for the hardware too, but there is none: we couldn't find a brand which produces its hardware in Europe and we couldn't find a hardware producer with the capacity and willingness to produce our hardware in Europe. So we chose the next best thing: a European company that has its own factory in Hong-Kong: Hong-Kong has much safer labor laws than other countries in Asia. And because the factory belongs to the French company, they must abide by labor laws and cannot just outsource to external suppliers and sweatshops - which is what often happens within the Fast Fashion supply chain (and FF brands don't care to investigate who actually made their clothes). This strategic choice proved us right: during the production process, we found 0 hardware piece with quality issues. We were able to use every single hardware piece for our bags.

The shoulder strap

The black JL shoulder strap has its own supply chain. The woven part of it is made in Spain, using 100% recycled polyester thread. Cotton wouldn't be resistant enough, the strap would eventually stretch and/or break - not an option. However by using recycled polyester, we do not add more polyester to the planet.

Note that the pattern on the strap is a woven jacquard: a complete custom development which took us several prototypes to get right.

The parts you can't see

Inside the bags, some elements are reinforced so that they are more durable and resistant. For instance, inside the handles, our atelier uses cork which is a natural and renewable resource. Where we need more surface and more padding, we use a material made in recycled cellulose, for instance inside the pouches where we wanted some cushioning.

If you bought a design made in canvas...

The main material

Instead of leather, we used 100% cotton canvas.

It is fabric purchased from another brand, which had overproduced and didn't use all the canvas it had produced. That fabric had the exact resistance and thickness we were looking for, so your bag is made in an upcycled fabric!

The canvas has no chemical finishing or coating on it, we just recommend that you spray it with a waterproofing product if you live in a region where rain and snow are common phenomena.

The patches and "vegan leather" elements

Some elements on a bag cannot be made in canvas, like the embossed logo patch on the front of your design, or the zipper pullers. There we used a leather alternative which contains only 1% PU (polyurethane). PU is oil-made, not biodegradable, and most products marketed as "vegan leather" are in fact 100% PU... Our material even contains 27% bio-based material, which is completely organic. It is the best alternative to leather we have found so far - and Justine has researched literally every producer of "vegan leather" out there.

Our material is made in Spain.

The lining

The lining for all the bags is GOTS-certified cotton canvas from Spain. "GOTS" means Global Organic Textile Standard: it's a reliable and globally recognized certification in terms of sustainability.

The cotton itself, from which the fabric is woven, comes from India. The fact that the final textile is GOTS-certified insures that there are no harmful chemicals used during the production of the fabric: among other things, it guarantees that no harmful chemicals are used in the fields, and therefore the GOTS certification protects the people working in those fields.

The hardware elements

What we call hardware are the metal elements of your bag. These are almost like a jewelry development: each part requires the creation of a unique mold, into which the material is poured. Then comes the polishing & plating steps, just like for jewelry. The only difference is we have 100% Sterling silver inside our jewelry, whereas for this handbag collection we use zamak. Zamak is a mix of several metals which is highly resistant, super durable, and more suited for handbags than solid silver. Silver is much more expensive but also too soft and too bendy for this purpose.

The hardware comes from a French company with a special setup: the technical development and the prototyping take place in France, the final production is in Hong-Kong and the quality control is in France. Initially, we wanted a European production for the hardware too, but there is none: we couldn't find a brand which produces its hardware in Europe and we couldn't find a hardware producer with the capacity and willingness to produce our hardware in Europe. So we chose the next best thing: a European company that has its own factory in Hong-Kong: Hong-Kong has much safer labor laws than other countries in Asia. And because the factory belongs to the French company, they must abide by labor laws and cannot just outsource to external suppliers and sweatshops - which is what often happens within the Fast Fashion supply chain (and FF brands don't care to investigate who actually made their clothes). This strategic choice proved us right: during the production process, we found 0 hardware piece with quality issues. We were able to use every single hardware piece for our bags.

The shoulder strap

The black JL shoulder strap has its own supply chain. The woven part of it is made in Spain, using 100% recycled polyester thread. Cotton wouldn't be resistant enough, the strap would eventually stretch and/or break - not an option. However by using recycled polyester, we do not add more polyester to the planet.

Note that the pattern on the strap is a woven jacquard: a complete custom development which took us several prototypes to get right.

The parts you can't see

Inside the bags, some elements are reinforced so that they are more durable and resistant. For instance, inside the handles, our atelier uses cork which is a natural and renewable resource. Where we need more surface and more padding, we use a material made in recycled cellulose - for instance inside the pouches, where we wanted some cushioning.

A note on branding and packaging

This is actually the first thing you'll see when you unpack your designs!

We use plastic-free packaging: the wavy cardboard your design is packed in is 100% recycled paper. The stuffing inside your bag is recycled paper as well.

Your design came with a hangtag: that is made in leather for the leather bags, and in cotton canvas for the canvas bags.

Note on the leather hangtags: Justine made a point of using as much of each cow hide as possible, to limit production waste. We didn't want to use "perfect leather" for the hangtags, so we used small rest pieces that couldn't be used for something else - this is why each hangtag looks a bit different, none of them looks like a proper square & some might even be uneven or have a scratch.

This is to show you a sample of the exact leather used for our bags, while limiting leather wastage.

We hope that you find this info and insight helpful. If you have further questions, you're welcome to write us an e-mail.

And if you'd like to join Justine's newsletter list, which is free, you can do so here: https://www.justineleconte.com/newsletter

Take care,

Team Justine